It has come to our attention that many companies want to help but do not know where to turn. We have N95 mask cut files and designs, gown cut files and designs, other PPE cut files and designs, and N95 mask material sources. If you’re a manufacturer and want to help but do not know where to start we have the resources available for free please contact us. If you have cut files and designs for PPE items you are making please come share them with the group. We have more than 25 companies participating as of March 26th.

We are open and here to serve you during the COVID-19 crisis, please contact us for detailed information on how we can help you.

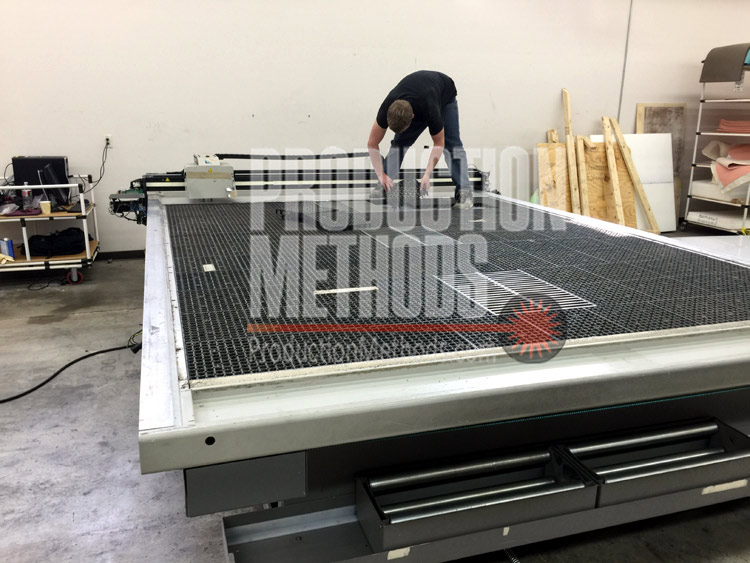

Production Methods has in-house textile fabric cutting and sewing capability available and also can connect companies with other cutting companies and sewers within their regional area.

We can also help with file development, tool pathing, and optimization advice for product flow as many of us are cutting or making things that are unfamiliar.

We have a couple of sources for patterns that are being made in various locations in the country which we are sharing and compiling new data to add to this knowledge. These files were originally posted by a customer in Washington State for public use and include a “how to” video for construction techniques.

We are vastly well-connected within the United States and can help make your connection for needed ramping up of production during this crisis in human history. This is not about money, it is bigger than that. We need supplies as a species, let’s get that done.

Please contact us through our website, call our main number at 716-568-1228, or via email to productive@productionmethods.com, and let us help you find the partner you need to make what is needed.

If you have production capabilities that are not being utilized we need to know that as well, so we can either connect you with a need, or help you get ramped up with your own projects.

Gerber DCS 2500 Maintenance procedures for small repetitive parts runs – such as face masks or other small medical consumable items. Change blades often, and round blades are generally the best for most mask fabrics. Lubricate X and Y axis guide rails every 6 to 8 hours or prior to each shift with a wet Teflon lubricant such as tri flow, LPS 3 or PB blaster with PTFE. Wet a rag with the lube and wipe on, spraying will lead to premature bearing failure. Check belts for cracks and pulleys for flanges coming free as well as the tension of the cutting belt on conveyor machines every 2 to 3 shifts. Check for loose rails in the x axis by pushing up with your thumb. It should not move at all, but especially at the ends of the rails. If it’s loose in the middle you can get by for a while but keep an eye on it. A loose end will destroy a linear bearing and MUST be tightened immediately. We have methods for doing this quickly, please contact us for details. Run short length files in a repetitive session with cut multiple. To make the machine repeat a short file down the table in CutWorks go to: “Machine” “Cut multiple” Select the number of runs you want to run. Set the buffer between the jobs from zero to whatever you would like, set “at end move to” to “clear end of job” and then hit start after checking start automatically. You may want to suppress interior cut off‘s as well and have it only cut off the material at the end of all the runs if it even does that. If you have multiple machines in your facility – even if you have different types – such as DCS 2500 machines or Taurus machines you can do the same function and have them all run the same pattern. This will make your operators more familiar with the motion of the production and therefore pick up issues earlier than they might otherwise, and the same goes for your maintenance people. They may even be able to hear if something is failing before they can actually see it. We are available for remote support, consumables and parts for the machines featured on our site.

Gerber DCS 3500 Maintenance procedures for small repetitive parts runs – such as facemasks or other small medical consumable items. Change blades often, and round blades are generally the best for most mask fabrics. Lubricate X and Y axis guide rails every 6 to 8 hours or prior to each shift with a wet Teflon lubricant such as tri flow, LPS 3 or PB blaster with PTFE. Wet a rag with the lube and wipe on, spraying will lead to premature bearing failure. Check belts for cracks and pulleys for flanges coming free as well as the tension of the cutting belt on conveyor machines every 2 to 3 shifts. Run short length files in a repetitive session with cut multiple. To make it repeat a short file down the table in CutWorks go to: “Machine” “Cut multiple” Select the number of runs you want to run. Set the buffer between the jobs from zero to whatever you would like, set “at end move to” to “clear end of job” and then hit start after checking start automatically. You may want to suppress interior cut off‘s as well and have it only cut off the material at the end of all the runs if it even does that. If you have multiple machines in your facility – even if you have different types – such as DCS 2500 machines or Taurus machines you can do the same function and have them all run the same pattern. This will make your operators more familiar with the motion of the production and therefore pick up issues earlier than they might otherwise, and the same goes for your maintenance people. They may even be able to hear if something is failing before they can actually see it. We are available for remote support, consumables and parts for the machines featured on our site.

Production Methods buys and sells parts for the machinery we sell and maintain. To learn more about buying parts visit our Supplies page or for selling used parts visit our Parts Procurement page.